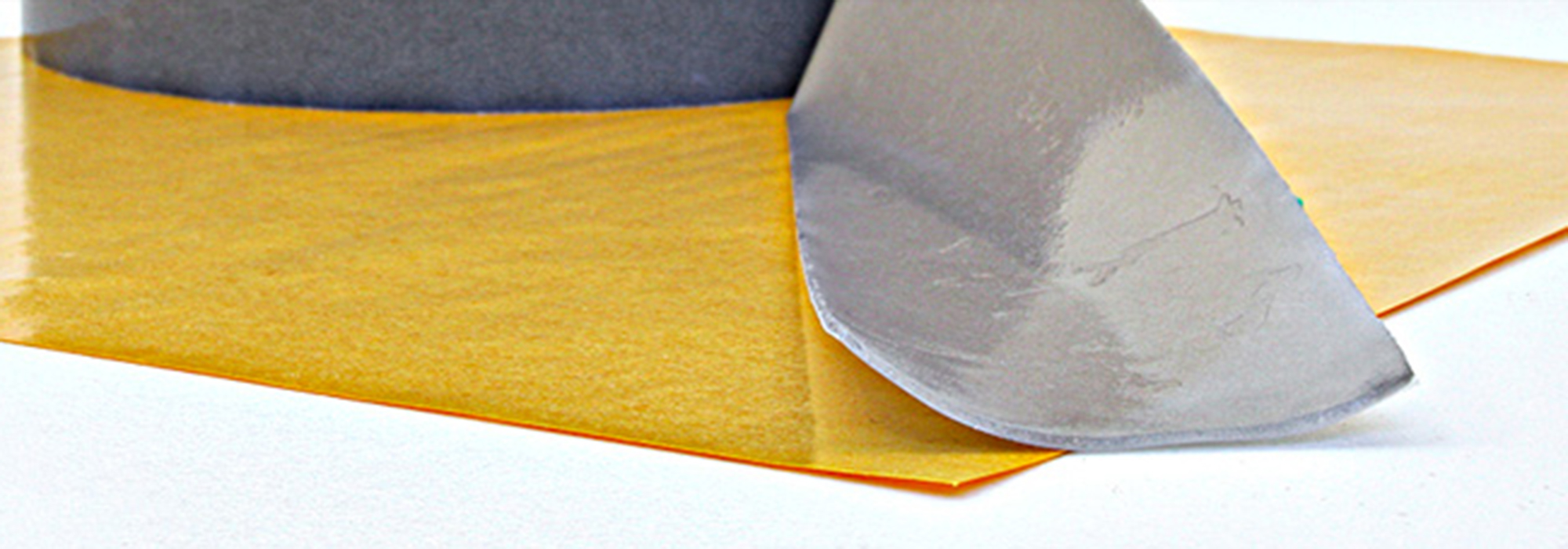

Thermo bonding film

Heat-activated tapes offer structural performance and can be used as a replacement for structural adhesives for permanent, clean bonds in industrial processes.

They are widely used in permanent assemblies in place of glues, creating stable and durable joints. They differ in the behavior of the partially adhesive side, their higher or lower activation temperatures, and the possibility of being partially pre-activated.

Structural Heat-activated Tapes

Heat-activated tapes can offer structural performance and be used as a replacement for structural adhesives for permanent, clean bonds in industrial processes. Their shape can sometimes be customized using a specific technical drawing provided to our technical team. The product has at least one inert side, known as non-adhesive at room temperature. This side can be activated with a solvent or by preheating at medium temperatures.

Among the main applications are:

1. attaching microchips to smart cards,

2. joining difficult materials (fiberglass, bituminous membranes),

3. joining very dissimilar materials (sheet metal/glass, gaskets/sheet metal).

Another difference between the various versions of these products is the reversibility of the bond: some are heat-activated (called reactivatable) and behave like hot melt adhesives, melting at high temperatures even after application.

Others cannot be reactivated because the cross-linking occurs through a thermosetting process, and subsequent heating is no longer able to dissolve the bonds: if the temperature is raised further, the adhesive dissolves and the bond breaks.